Tel:021-68620038 Email: soryer@soryer.cn

CMP Slurry

Detailed Introduction

GPX is a polishing slurry for CMP(Chemical Mechanical Planarization). GPX achieves excellent polishing performance, is

applicable to finer patterns and suitable for the fabrication of semiconductor devices.

This unique slurry series is also available for various applications except semiconductor devices.

Series Line-up & Features

The GPX slurry series is capable of meeting various polishing requirements as Si, SiO2 and etc., Metals as Cu, Ta, Al and etc. Applicable to polymer, Al2O3 and etc. (More information, please click series name).

| Products Series | Recommended Polishing Application | Features of each series |

|---|---|---|

| HS-8005 | SiO2/glass | CeO2 slurry for semiconductor STI process, polishing SiO2 and glass. High removal rate for SiO2. |

| HS-C, H | Cu | Slurry for polishing semiconductor Cu line, achieving high removal rate of Cu. |

| HS-T | Ta/TaN/Ti | Slurry for polishing semiconductor Cu barrier metals. Alternative of Selective/Non-selective polishing. |

| HS-A | Al | Slurry for polishing aluminum. |

| HS-P | Si | Slurry for polishing Si, p-Si. Selective polishing for Si and p-Si. |

| HS-S | Si | Slurry for polishing Si and back side of TSV substrate. Non-selective polishing for Si/SiO2/Cu |

| HS-J | others | Slurry for polishing other metals and materials. Applicable to epoxy polymer, aluminum(sapphire) polishing. |

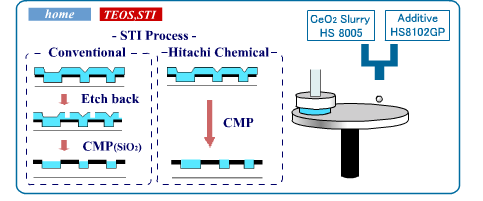

HS-8005 Series (Polishing Slurry for SiO2, Glass)

CMP Process

Advanced semiconductor devices with high performance are required to have multi-level layers and fine patterns to obtain high speed transmission.

HS-8005 series containing abrasive particles of CeO2 are available for planarization of STI and ILD.

GP additives work to improve the performance of planarity and others.

Features

High removal rate for SiO2

Free from scratches by using tuned CeO2 particles.

High removal rate at low slurry content (CeO2:1%).

High planarization and selectivity between SiO2 and Si3N4.

Elimination of conventional etch back process

Removal Rate

| Product series | Removal rate* (nm/min) | ||

|---|---|---|---|

| SiO2 | SiN | Poly-Si | |

| HS-8005 | 300 | 10 | 1 |

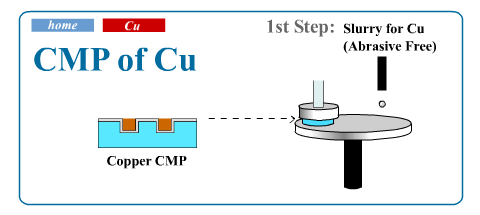

HS-C, T, A Series (Polishing Slurry for Cu, Ta, Al Metals)

CMP Process

Low dishing and erosion.

Removal selectivity of Cu, TaN, and oxide is tunable.

Features of Each Series

| Product series | Features / Applications |

|---|---|

| HS-C, HS-H | For Cu polishing. Removal rate from 1000-5000nm/min |

| HS-T | For Cu barrier metal and SiO2 polishing. Alternative of high selective/non-selective polishing slurry. |

| HS-A | For aluminum polishing. |

Removal Rate of Each Series

| Product series | Removal rate* (nm/min) | |||||

|---|---|---|---|---|---|---|

| Cu | Ta/TaN | SiO2 | SiOC | Al | ||

| HS-C | High removal rate | 5,000 | 60 | 10 | – | – |

| HS-H | Standard | 1,000 | <1 | <1 | – | – |

| HS-T | High selective | 40 | 80 | 5 | 5 | – |

| Non selective | 40 | 90 | 90 | 40 | – | |

| HS-A | – | – | 100 | – | 200 | |

HS-P, S Series (Polishing Slurry for Si )

Features of Each Series

| Product series | Features / Applications |

|---|---|

| HS-P | For Si and p-Si polishing. Two component type mixing with P100 series and P200 series. High selective polishing of SiO2/Si/p-Si. |

| HS-S | For TSV back side polishing. Two component type mixing with S100 series and S200 series. Non-selective polishing of Si/SiO2/Cu. |

Removal Rate of Each Series

| Product series | Removal rate* (nm/min) | ||||

|---|---|---|---|---|---|

| p-Si | Si | SiO2 | Cu | ||

| HS-P100/P200 | Si/SiO2, High selective | 300-600 | 700-1,500 | 0.1-15 | 200 |

| HS-S100/S200 | Si/SiO2/Cu, Non selective | 400 | 1,200 | 400 | 1,000 |

| SiO2/Cu, Non selective | 50 | 100 | 700 | 600 | |

HS-J Series (Polishing Slurry for Other Metals and Materials)

Features

Applicable for polishing of Epoxy polymer, aluminum layer and etc.

Applicable for polishing of Cu, permalloy and etc.

Removal Rate

| Product series | Removal rate* (nm/min) | |||

|---|---|---|---|---|

| Resin (epoxy, etc.) | Al2O3 | Permalloy | Cu | |

| HS-J700-1 | 500 | 800-1,000 | 200 | 100 |

*The removal rate is typical value and adjustable by polishing condition and slurry mixture ratio.

![]()

Or consult the Sales Department : sales@soryer.cn

Copyright 2018 all right reserved. Shanghai Soryer International Trading Co.,Ltd.

ICP备案号:沪ICP备2022028270号

Contact Us

Tel: 0086(+21)68620038

Email: soryer@soryer.cn

Headquarter: Rm 405,4F,Building3,No.188.AoNa Rd ,Pilot Free-Trade Zone,Shanghai

Soryer Always Backs You up!